Specialized design and construction based on product characteristics and scientific and rigorous production processes and procedures, with the world's leading manufacturing level and technical capabilities.

The factory realizes the high standard of consistency, and the equipment of each process ensures high precision and reliability, and the manufacturing precision of the important process links of the production line reaches the leading level in the industry.

This is the "main factory" for the R&D and production of XFC high-speed battery cells and related new energy storage devices as well as their PACK integration systems, with a total capacity of 8 GWh/year, and the capacity of the factory that has already been put into operation is 4 GWh.

Greater Bay Technology achieves double breakthroughs in technological innovation and manufacturing, and promotes the automotive traction battery industry to high-end, intelligent and high-quality development.

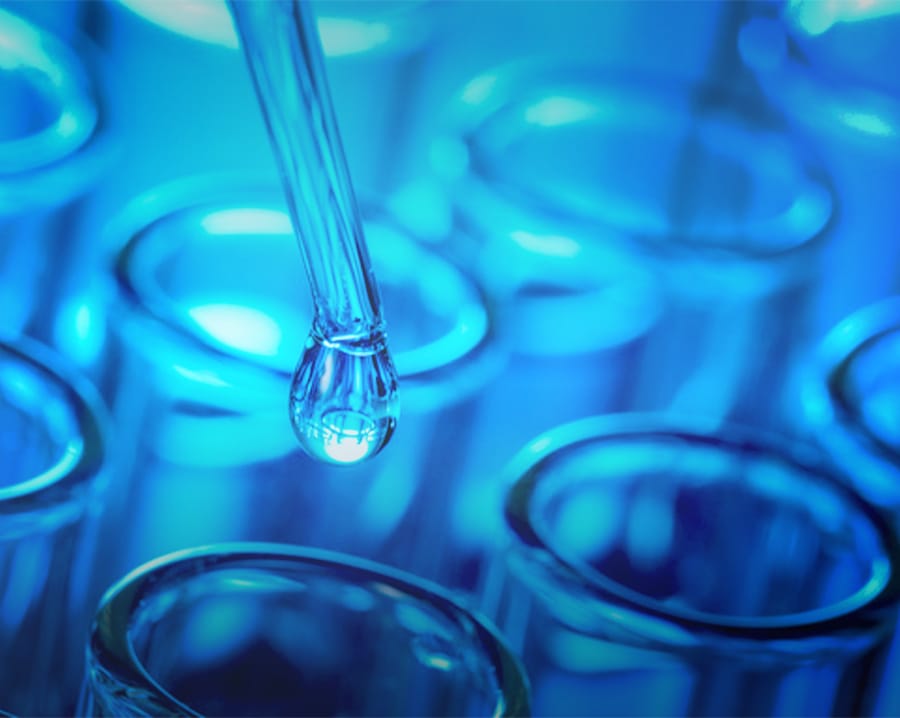

Proprietary functionalized electrolytes combined with a precisely optimized formation process allow the cells to be continuously charged at high rates and maintain an ultra-long cycle life.

Multi-group high-precision feeding system combined with raw material pre-mixing system and high-speed homogenizing system makes the prepared electrode sheet have excellent electrochemical, thermodynamic and mechanical properties.

Unlike ordinary batteries, the ultra-wide lug design effectively reduces resistance and temperature rise during high-speed charging, and ensures battery reliability and safety.

Multi-layer coating technology combined with optimized electrode material system can realize eXtreme Fast Charging under the conditions of high energy density, long life and low cost.

Stringent environmental humidity and cleanliness control, far higher than the industry's environmental standards, can ensure the consistency of super-charged battery products and ultra-high safety and reliability.